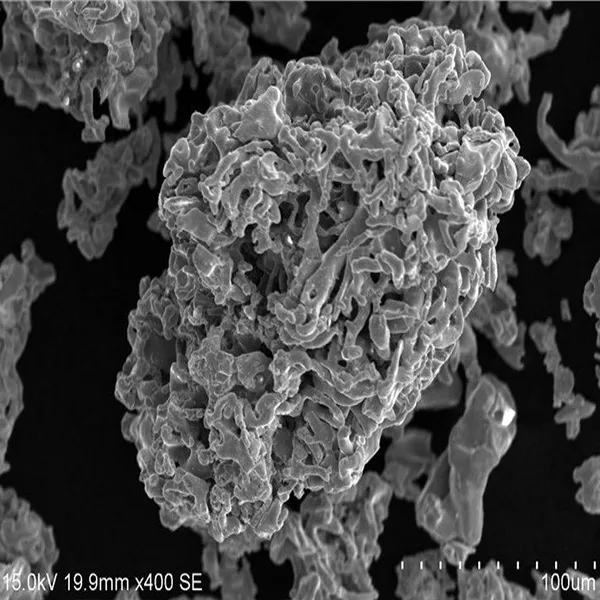

Currently, with the upgrading of the manufacturing industry structure, the powder metallurgy industry is gradually transitioning toward high performance, high density, and low energy consumption. As a foundational component of the supply chain, iron powder materials are also exhibiting the following trends:

Process refinement: More detailed requirements are being placed on particle size distribution, powder flowability, and pressing performance;

Product Diversification: Growing demand for customization, with some companies beginning to offer specialized powder formulations or multiple blending solutions;

Expanded Application Areas: Beyond traditional structural components, iron powder is being explored for use in emerging fields such as magnetic materials, energy storage, and 3D printing;

Environmental Protection and Energy Consumption Control: Green manufacturing has become a common goal for industry development, with energy efficiency in powder preparation and sintering stages receiving increased attention.