The preparation method of iron powder directly affects its physical properties and application scenarios. The main methods include the following:

Reduced iron powder: Obtained by reducing iron oxide, it has lower costs and is suitable for large-scale production of structural components;

Water-atomized iron powder: Metal is melted and cooled into powder using water spray, with a wide particle size distribution, suitable for pressing and sintering;

Gas-atomized iron powder: Features more regular particle morphology and finer particle size, commonly used in injection molding and precision components;

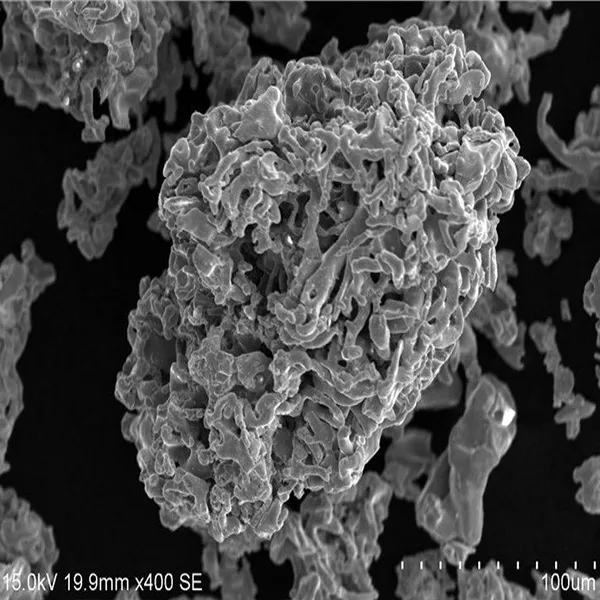

Electrolytic iron powder: High purity and large surface area, primarily used in magnetic materials or high-end custom applications.

As terminal manufacturing demands for material consistency, density, and sintering performance continue to rise, the customization capabilities and batch stability of iron powder products have become key market focuses.