Normally,a typical oxy-fuel flame cannot generate sufficient heat to cut materials such as stainless steel due to the formation of heat resistant slag. Powder cutting, in which iron powder is added to the flame, has a twofold effect. Firstly, the burning (oxidation) of the iron powder provides a higher cutting temperature. Secondly, the heat-resistant slag is diluted by the oxidised iron powder, causing a decrease of the slag melting temperature. This results in a more fluid slag that can easily be removed by the oxygen stream

EmailMore

LWR80、LWLD80

EmailMore

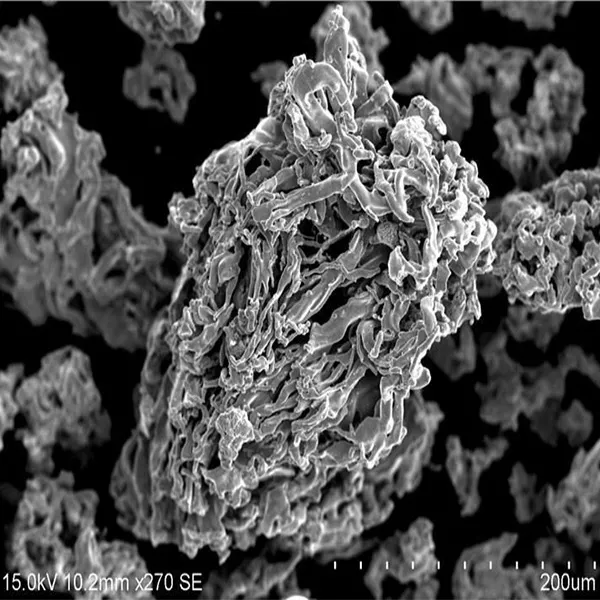

LAP40.37 is a high density water atomized iron powder with low carbon and oxygen content, and it exhibits high consistency in chemical composition and particle size distribution. These characteristics give it exceptional purity and performance stability. This powder is particularly suitable for applications requiring high purity and excellent welding performance, such as alkaline coated electrodes, flux-cored wires, and metal-cored wires. Its high density not only enhances the overall performance of the filler materials but also significantly improves the stability and efficiency of the welding process.

EmailMore

LAP40.30 is a medium-density water-atomized iron powder featuring low carbon and oxygen content. Its particle size and powder density have been specifically optimized for use in alkaline coated electrodes. This powder offers excellent electrical conductivity and low impurity levels, leading to enhanced production efficiency and improved electrode welding performance.

EmailMore

LAP100.29A1、LAP100.29A2、LAP100.29A3、LAP100.29A4、LAP100.29Mo1、LAP100.29Mo2、LAP100.29Mo3、LAP100.29S1、LAP100.29P1

EmailMore

LAP100.29H is a type of ultra-pure water atomised iron powder, with AD 2.95-3.10g/cm3, with good compression performance, and is widely used in high strength, high density sintered structural PM parts....

EmailMore