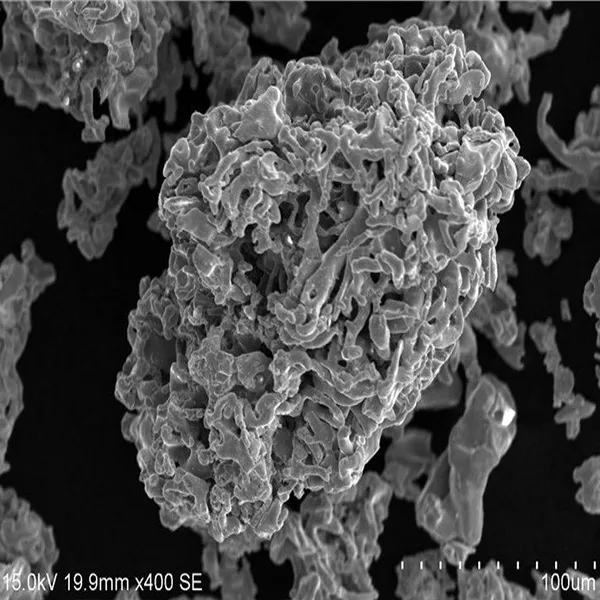

Iron powder is one of the most widely used basic raw materials in powder metallurgy processes, characterized by abundant resources, relatively low cost, and broad applicability. In industries such as automotive components, mechanical manufacturing, and magnetic components, parts formed by pressing iron powder have become an integral part of standardized production processes. Depending on the preparation method, iron powder can be classified into reduced iron powder, water-atomized iron powder, and electrolytic iron powder, among others, with products from the reduction and atomization methods being the most widely applied.

Powder metallurgy components offer certain advantages over traditional processing methods in terms of material utilization, complex shape processing, and dimensional consistency. As downstream industries demand higher precision and performance, iron powder products are also evolving in terms of particle size control, purity adjustment, and additive compatibility.