Recently, Dazhong Daily · Haibao News released a documentary series titled “Leap”, highlighting the remarkable achievements of Shandong metallurgical enterprises in digital transformation. As a representative enterprise, Luyin Powders was featured for its successful digital upgrade and innovative breakthroughs, demonstrating a comprehensive transformation from traditional manufacturing to intelligent manufacturing.

Selected as a National 5G Smart Factory

Recently, Luyin Powders was officially selected for the 2025 National 5G Factory Directory issued by the Ministry of Industry and Information Technology of China, in recognition of its advanced application of 5G technology in industrial manufacturing.

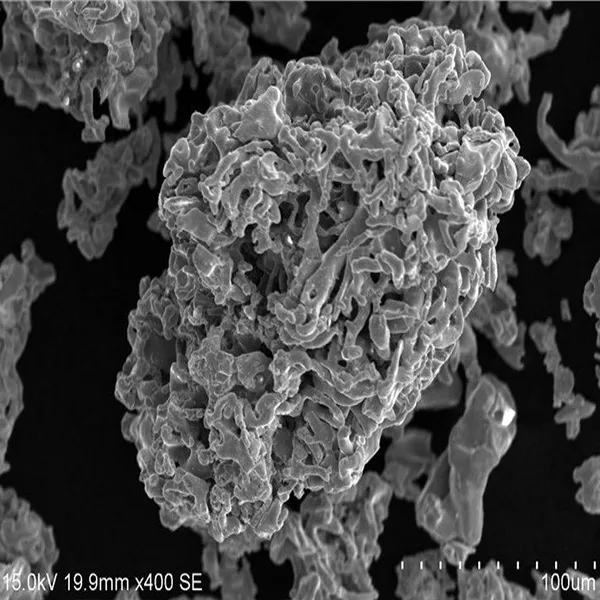

With an annual production capacity of 250,000 tons of metal powders and a domestic market share exceeding 30%, Luyin Powders is a leading enterprise in China’s powder metallurgy industry. The company is actively advancing its transformation from “manufacturing” to “intelligent manufacturing”, setting a benchmark for the industry.

Building a Digital Foundation with a 5G Private Network

The cornerstone of Luyin Powders’ transformation lies in the deployment of a 5G private network covering the entire factory. Acting as the enterprise’s “digital nervous system,” the network connects previously isolated production processes with high speed, low latency, and high stability, enabling seamless data flow across the manufacturing chain.

As Vice General Manager Yu Yongliang explained,

“This transformation is tangible. In the past, production stages were separated like isolated islands, and information had to pass through multiple layers. Now, with a single order, instructions are delivered directly to production posts, allowing us to monitor the entire production process in real time.”

Previously, handling a production abnormality could take several hours. Today, the digital system can automatically monitor equipment status, issue early warnings, and pinpoint problems, improving response efficiency by several times and significantly enhancing production stability and continuity.

Data-Driven Management Across the Entire Value Chain

According to Qiao Kun, Assistant Director of the Enterprise Management Department, 5G technology has enabled a full-chain data synergy revolution. Intelligent sensors and real-time data acquisition systems deployed throughout the factory ensure that every production parameter and quality inspection result is uploaded instantly.

This data-driven management approach has led to a substantial upgrade in the company’s quality management system. In addition, warehouse management has achieved precision control, with real-time inventory updates enabled by barcode scanning.

Empowering R&D through Digital Innovation

Even more profound changes are taking place in the research and development domain. As a leading enterprise in China’s powder metallurgy industry, Luyin Powders offers three major product categories and more than 600 metal powder products, with breakthroughs in high-end materials forming the core of its long-term strategy.

Vice General Manager Zhang Dejin noted that digitalization is reshaping the R&D model:

“In the past, developing new products required repeated trial-and-error. Today, we can extract full-process data from any batch, analyze process parameters precisely, and optimize them in reverse.”

This data-driven R&D capability provides strong support for the development of advanced materials, including powders for additive manufacturing (3D printing) and laser cladding.

Digitalization as a Strategic Engine for High-Quality Growth

From a strategic perspective, Wang Changdong, Party Secretary and Chairman of Luyin Powders, emphasized that digitalization is a key enabler for cultivating new-quality productive forces.

“Digitalization is not just a technical tool; it is a critical driver of enterprise transformation and upgrading.”

Through digital transformation, Luyin Powders has shifted its strategic focus from large-scale production to high-end manufacturing, providing more reliable and cutting-edge material solutions for downstream industries such as automotive, aerospace, and new energy.

“Digitalization is the foundation of our transition from a traditional material supplier to an innovation-driven enterprise,” Wang added.

Forging a New Path for Intelligent Manufacturing

Anchored by 5G digital infrastructure and driven by data as the core engine, Luyin Powders has pioneered a new pathway for the intelligent transformation of traditional manufacturing.

Looking ahead, Luyin Powders plans to further integrate advanced digital technologies with manufacturing, continuously redefining the value of ‘Steel Manufacturing’ through intelligent solutions, and contributing to the high-quality development of Made in China with innovation and strength.